Call Us: (816) 307-7991

Email Us: mark@andersonmechanicalkc.com

Office Hours: Mon - Fri: 8:00 am - 4:00 PM | 24/7 After Hours Service Available

Maximizing Efficiency and Comfort: The Comprehensive Guide to Boiler and Chiller Installation with Anderson Mechanical KC

Unlocking Efficiency and Comfort: The Ultimate Guide to VRF Installation with Anderson Mechanical KC

In the realm of heating, ventilation, and air conditioning (HVAC) systems, boilers and chillers play pivotal roles in maintaining optimal indoor climates. Whether it's ensuring warmth during the chilly months or providing cool relief in the scorching heat, these systems are indispensable for both commercial and residential spaces. Anderson Mechanical KC stands as a beacon of excellence in the HVAC industry, offering top-tier boiler and chiller installation services that promise enhanced efficiency, reliability, and comfort. This comprehensive guide delves into the intricacies of boiler and chiller systems, explores the benefits of choosing Anderson Mechanical KC for your installation needs, and provides insights into how these systems can revolutionize your indoor environment.

Understanding Boilers and Chillers: The Backbone of HVAC Systems

Before delving into the specifics of installation, it's crucial to grasp what boilers and chillers are, how they function, and why they are essential components of modern HVAC systems.

What is a Boiler?

A boiler is a closed vessel that heats water or generates steam by applying heat energy. The heated or vaporized fluid exits the boiler for use in various applications such as heating, power generation, and industrial processes. In HVAC systems, boilers are primarily used to provide space heating and domestic hot water.

How Do Boilers Work?

Boilers operate by burning a fuel source (such as natural gas, oil, or electricity) to produce heat. This heat is transferred to water, creating either hot water or steam, which is then distributed throughout the building via radiators, baseboards, or underfloor heating systems. The controlled temperature ensures consistent and comfortable indoor environments.

What is a Chiller?

A chiller is a machine that removes heat from a liquid via a vapor-compression or absorption refrigeration cycle. The chilled liquid is then circulated through a heat exchanger to cool air or equipment in various applications, including air conditioning systems, industrial processes, and large buildings.

How Do Chillers Work?

Chillers function by absorbing heat from the liquid circulating through them and transferring it to the surrounding environment. This process involves a refrigerant that undergoes phase changes from liquid to gas and back, efficiently removing heat and providing the necessary cooling effect. The chilled liquid is then used to cool the air in the building or process equipment, ensuring optimal temperature control.

Components of Boiler and Chiller Systems

Both boiler and chiller systems consist of several key components that work in harmony to deliver efficient heating and cooling:

Boiler System Components:

- Burner: Combusts the fuel to produce heat.

- Heat Exchanger: Transfers heat to the water or steam.

- Pump: Circulates the heated water or steam through the distribution system.

- Control System: Manages the operation of the boiler, ensuring optimal performance and safety.

- Safety Devices: Include pressure relief valves and temperature sensors to prevent overheating and over-pressurization.

Chiller System Components:

- Compressor: Compresses the refrigerant, increasing its pressure and temperature.

- Condenser: Releases the absorbed heat from the refrigerant to the environment.

- Evaporator: Absorbs heat from the liquid being cooled.

- Expansion Valve: Regulates the flow of refrigerant into the evaporator.

- Control System: Oversees the chiller’s operation, maintaining desired temperatures and efficiency.

The Advantages of Boiler and Chiller Installation

Investing in high-quality boiler and chiller systems offers numerous benefits that significantly enhance the comfort, efficiency, and sustainability of your indoor environment. Here's why boiler and chiller installation is a smart choice for both commercial and residential spaces.

1. Enhanced Energy Efficiency

Modern boilers and chillers are designed with energy efficiency in mind. Advanced technologies such as condensing boilers and variable speed compressors in chillers ensure that energy consumption is optimized based on real-time demand. This leads to substantial reductions in utility bills and minimizes the environmental impact by lowering carbon emissions.

2. Superior Comfort and Precision

Boilers and chillers provide precise control over indoor temperatures, ensuring consistent and comfortable environments regardless of external weather conditions. With zoned heating and cooling capabilities, different areas of a building can maintain individual temperature settings, catering to the specific needs of occupants and enhancing overall comfort.

3. Reliability and Longevity

High-quality boiler and chiller systems are built to last, offering reliable performance over extended periods. Regular maintenance and professional installation, such as those provided by Anderson Mechanical KC, ensure that these systems operate efficiently and have a longer lifespan, reducing the need for frequent replacements and repairs.

4. Flexible and Scalable Solutions

Boiler and chiller systems are highly adaptable to various building sizes and configurations. Whether you're managing a large commercial complex or a multi-story residential building, these systems can be customized and scaled to meet specific heating and cooling requirements, providing flexibility for future expansions or modifications.

5. Reduced Installation Space

Modern boiler and chiller systems are designed to be compact and space-efficient. They require less physical footprint compared to older models, freeing up valuable space for other essential uses within a building. This is particularly advantageous in urban settings where space is often at a premium.

6. Environmental Sustainability

By leveraging energy-efficient technologies and eco-friendly refrigerants, boiler and chiller systems contribute to sustainability efforts. Reduced energy consumption translates to lower greenhouse gas emissions, aligning with global initiatives to combat climate change and promote environmental stewardship.

7. Quiet Operation

Advancements in boiler and chiller technologies have led to significantly quieter operations. Noise-reduction features and insulated components ensure that these systems operate discreetly, enhancing the comfort of indoor environments without the distraction of excessive noise.

Why Choose Anderson Mechanical KC for Boiler and Chiller Installation?

Selecting the right service provider is crucial to ensure the successful installation and operation of your boiler and chiller systems. Anderson Mechanical KC distinguishes itself in the HVAC industry through its unwavering commitment to quality, expertise, and customer satisfaction. Here's why Anderson Mechanical KC should be your go-to choice for boiler and chiller installation.

Expertise and Experience

With years of experience in the HVAC sector, Anderson Mechanical KC boasts a team of highly trained professionals adept at handling the complexities of boiler and chiller systems. Their in-depth knowledge ensures that every installation is executed with precision, adhering to industry standards and best practices.

Customized Solutions

Recognizing that each building has unique heating and cooling requirements, Anderson Mechanical KC offers tailored boiler and chiller solutions designed to meet specific needs. From system design to component selection, their personalized approach guarantees that the installed systems align perfectly with the client's objectives and building specifications.

Quality Assurance

Quality is at the heart of Anderson Mechanical KC's operations. They utilize top-of-the-line boiler and chiller components from reputable manufacturers, ensuring reliability and durability. Rigorous quality checks are conducted at every stage of the installation process, safeguarding the system's performance and longevity.

Comprehensive Support

Anderson Mechanical KC provides end-to-end support, from initial consultation and system design to installation and ongoing maintenance. Their commitment to customer satisfaction extends beyond installation, offering maintenance services that keep the boiler and chiller systems running efficiently year-round.

Competitive Pricing

Understanding the importance of cost-effectiveness, Anderson Mechanical KC offers competitive pricing without compromising on quality. Their transparent pricing model ensures that clients receive value for their investment, making boiler and chiller installation an affordable and worthwhile endeavor.

Timely Execution

Time is often of the essence in HVAC installations, and Anderson Mechanical KC excels in delivering timely solutions. Their streamlined processes and efficient project management ensure that installations are completed within the stipulated timeframe, minimizing disruptions to the client's operations or daily life.

Positive Customer Reviews

A testament to their excellence, Anderson Mechanical KC boasts a portfolio of satisfied clients who have benefited from their boiler and chiller installation services. Positive testimonials highlight their professionalism, technical prowess, and dedication to customer satisfaction, reinforcing their reputation as a trusted HVAC service provider.

The Boiler and Chiller Installation Process with Anderson Mechanical KC

Embarking on a boiler and chiller installation project with Anderson Mechanical KC involves several key steps, each meticulously planned and executed to ensure a seamless and successful outcome. Here's an overview of the typical installation process:

1. Initial Consultation and Assessment

The journey begins with an initial consultation where Anderson Mechanical KC's experts assess the client's heating and cooling needs. This involves evaluating the building's layout, existing HVAC infrastructure, and specific requirements to determine the most suitable boiler and chiller system configuration.

2. System Design and Planning

Based on the assessment, a customized boiler and chiller system design is developed. This includes selecting the appropriate units, determining piping and ductwork routes, and planning the control systems. Advanced software tools may be utilized to model the system's performance, ensuring optimal efficiency and coverage.

3. Equipment Selection and Procurement

Anderson Mechanical KC sources high-quality boiler and chiller components from reputable manufacturers. This ensures that the systems' performance aligns with industry standards and client expectations. Attention is paid to selecting equipment that offers reliability, efficiency, and compatibility with the building's requirements.

4. Installation Preparation

Prior to installation, the team prepares the site by coordinating with the client to schedule the work, securing necessary permits, and ensuring that all components are ready for deployment. This phase may also involve addressing any structural or infrastructural modifications required to accommodate the new systems.

5. Installation of Boilers and Chillers

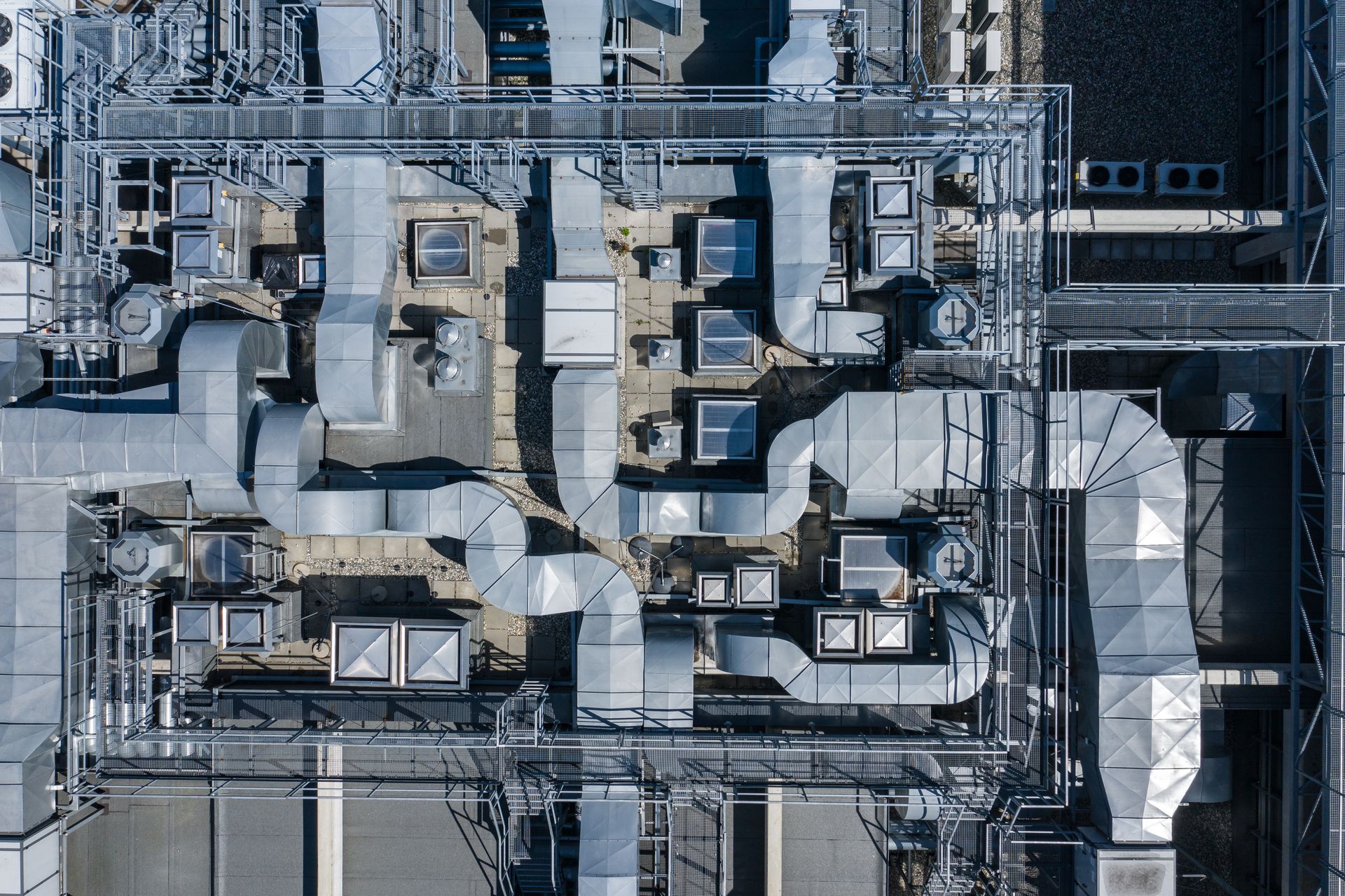

The installation process commences with setting up the outdoor and indoor units, ensuring they are positioned for optimal performance and easy maintenance access. Precise installation of piping, ductwork, and electrical connections is paramount to ensure system integrity and efficiency.

6. Refrigerant Piping and Electrical Connections

Precision is essential in laying out the refrigerant piping and electrical connections, as they form the backbone of the boiler and chiller systems. Proper insulation and sealing are crucial to prevent leaks and maintain system efficiency. Simultaneously, electrical connections are established to integrate the systems with the building's power supply and control mechanisms.

7. System Integration and Testing

Once all components are in place, the boiler and chiller systems are integrated and thoroughly tested. This involves verifying the functionality of each unit, calibrating temperature controls, and ensuring seamless communication between components. Comprehensive testing guarantees that the systems operate at peak performance.

8. Client Training and Handover

Anderson Mechanical KC ensures that clients are well-versed in operating and maintaining their new boiler and chiller systems. Training sessions cover the use of control interfaces, routine maintenance practices, and troubleshooting procedures. The handover process is conducted with meticulous attention to detail, ensuring that clients are fully equipped to manage their HVAC systems.

9. Ongoing Maintenance and Support

Post-installation, Anderson Mechanical KC offers ongoing maintenance services to uphold the systems' efficiency and longevity. Regular inspections, cleaning, and prompt repairs are part of their commitment to sustained performance and client satisfaction.

Applications of Boiler and Chiller Systems: Versatility Across Various Sectors

Boiler and chiller systems are renowned for their versatility, making them suitable for a wide range of applications across different sectors. Here's a glimpse into where these installations can make a significant impact:

1. Commercial Buildings

From office complexes and retail spaces to hotels and restaurants, boiler and chiller systems cater to the diverse climate control needs of commercial establishments. Their ability to handle multiple zones with varying temperature requirements makes them ideal for businesses seeking both efficiency and flexibility.

2. Residential Properties

Homeowners benefit from boiler and chiller systems through personalized comfort settings and energy savings. Whether it's a single-family home or a multi-unit residential building, these installations provide reliable heating and cooling solutions that enhance the living experience.

3. Healthcare Facilities

Hospitals, clinics, and other healthcare facilities demand precise climate control to ensure patient comfort and maintain sterile environments. Boiler and chiller systems offer the necessary reliability and control, making them a preferred choice in the healthcare sector.

4. Educational Institutions

Schools, colleges, and universities require robust HVAC solutions to accommodate varying occupancy levels and diverse space usages. Boiler and chiller systems provide the flexibility and efficiency needed to create comfortable learning and working environments.

5. Industrial Settings

Manufacturing plants and warehouses often have unique HVAC requirements due to their size and operational demands. Boiler and chiller systems offer scalable solutions that can adapt to the dynamic needs of industrial spaces, ensuring optimal indoor conditions and process efficiency.

Maximizing the Benefits of Boiler and Chiller Systems: Tips and Best Practices

To fully harness the advantages of boiler and chiller systems, it's essential to adhere to certain best practices and maintenance tips. Here are some recommendations to ensure your installation continues to deliver optimal performance:

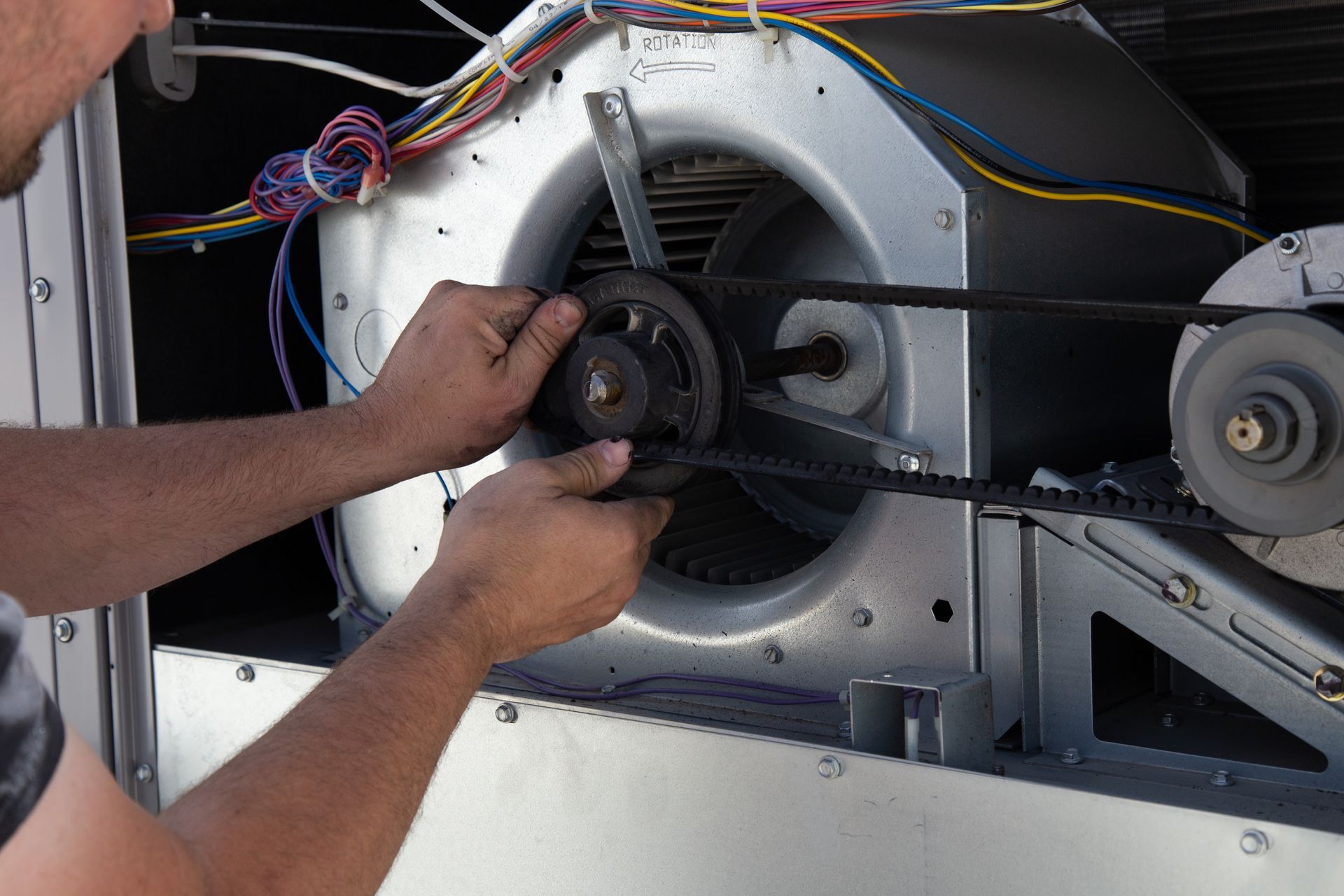

1. Regular Maintenance

Scheduled maintenance is crucial for the longevity and efficiency of your boiler and chiller systems. Engage Anderson Mechanical KC for routine inspections, cleaning, and component checks to prevent potential issues and maintain system integrity.

2. Optimal System Design

Ensure that the boiler and chiller systems are designed to match the specific needs of your building. Factors such as insulation, window placement, and occupancy levels should be considered to optimize system performance and energy efficiency.

3. Proper Installation

The success of boiler and chiller systems hinges on meticulous installation. Partnering with experienced professionals like Anderson Mechanical KC ensures that all components are correctly installed, reducing the risk of future malfunctions and maximizing efficiency.

4. Utilize Advanced Controls

Modern boiler and chiller systems come equipped with sophisticated control interfaces that allow for precise temperature management and energy monitoring. Leveraging these controls can enhance system performance and provide valuable insights into energy usage patterns.

5. Address Issues Promptly

Any signs of system irregularities, such as unusual noises, inconsistent temperatures, or error alerts, should be addressed immediately. Prompt attention to these issues can prevent minor problems from escalating into costly repairs.

6. Educate Occupants

Educating the occupants of your building on the proper use of the boiler and chiller systems can significantly impact their efficiency. Simple practices, such as adjusting thermostat settings appropriately and ensuring vents are not obstructed, contribute to optimal performance.

The Future of HVAC: Embracing Advanced Boiler and Chiller Technologies

As the demand for energy-efficient and flexible HVAC solutions continues to rise, boiler and chiller technologies are poised to play a pivotal role in shaping the future of indoor climate control. Innovations in these systems promise even greater efficiency, sustainability, and ease of use.

Integration with Smart Building Technologies

The integration of boiler and chiller systems with smart building technologies is set to revolutionize HVAC management. By leveraging Internet of Things (IoT) devices and advanced analytics, these systems can offer predictive maintenance, real-time energy monitoring, and adaptive climate control, further enhancing their efficiency and user-friendliness.

Sustainable Fuel Sources and Refrigerants

Environmental considerations are driving the adoption of sustainable fuel sources and eco-friendly refrigerants in boiler and chiller systems. Utilizing renewable energy sources and refrigerants with lower global warming potentials (GWPs) aligns with global efforts to reduce greenhouse gas emissions and combat climate change.

Enhanced Modular and Scalable Designs

Future boiler and chiller systems are expected to feature even more modular and scalable designs, facilitating easier expansions and retrofits. This flexibility will make these systems accessible to a broader range of applications, from small residential buildings to large-scale industrial complexes.

Improved Energy Recovery Systems

Advancements in energy recovery technologies will enable boiler and chiller systems to reclaim and reuse waste heat, further boosting their energy efficiency. These systems can capture excess heat generated during operation and redirect it for other uses, reducing overall energy consumption.

Conclusion: Elevate Your Indoor Environment with Anderson Mechanical KC's Boiler and Chiller Installation Services

In the pursuit of superior indoor climate control, boiler and chiller systems stand out as essential components that offer unmatched efficiency, reliability, and comfort. Anderson Mechanical KC, with its expertise in boiler and chiller installation, provides a pathway to harnessing these benefits, transforming your space into an environment that prioritizes both occupant satisfaction and energy sustainability.

Whether you're managing a commercial establishment seeking to optimize operational costs or a homeowner aiming for personalized comfort, boiler and chiller systems installed by Anderson Mechanical KC can be the solution you need. Their commitment to quality, personalized service, and ongoing support ensures that your investment in these advanced HVAC technologies yields long-term rewards.

Embrace the future of HVAC with Anderson Mechanical KC's boiler and chiller installation services and experience a harmonious blend of innovation, efficiency, and comfort. Reach out today to explore how these systems can revolutionize your indoor environment.

Boosting Energy Efficiency in Commercial Buildings: Smart HVAC Strategies for Kansas City Businesses

Unlocking Efficiency and Comfort: The Ultimate Guide to VRF Installation with Anderson Mechanical KC

Contact

Kansas City, MO; Lee Summit; Kansas City, KS; Johnson County; Jackson County

Subscribe

Subscribe for the latest news, updates, and insights from Anderson Mechanical.

Contact Us

We will get back to you as soon as possible.

Please try again later.