Call Us: (816) 307-7991

Email Us: mark@andersonmechanicalkc.com

Office Hours: Mon - Fri: 8:00 am - 4:00 PM | 24/7 After Hours Service Available

What to Know About Professional Compressor Installation for Your Facility

What to Know About Professional Compressor Installation for Your Facility

When it comes to running an efficient commercial or industrial facility, your air compressor system is more important than you might think. It powers everything from pneumatic tools and production machinery to HVAC systems and packaging lines. But getting the most out of your compressor starts with one key step: professional installation.

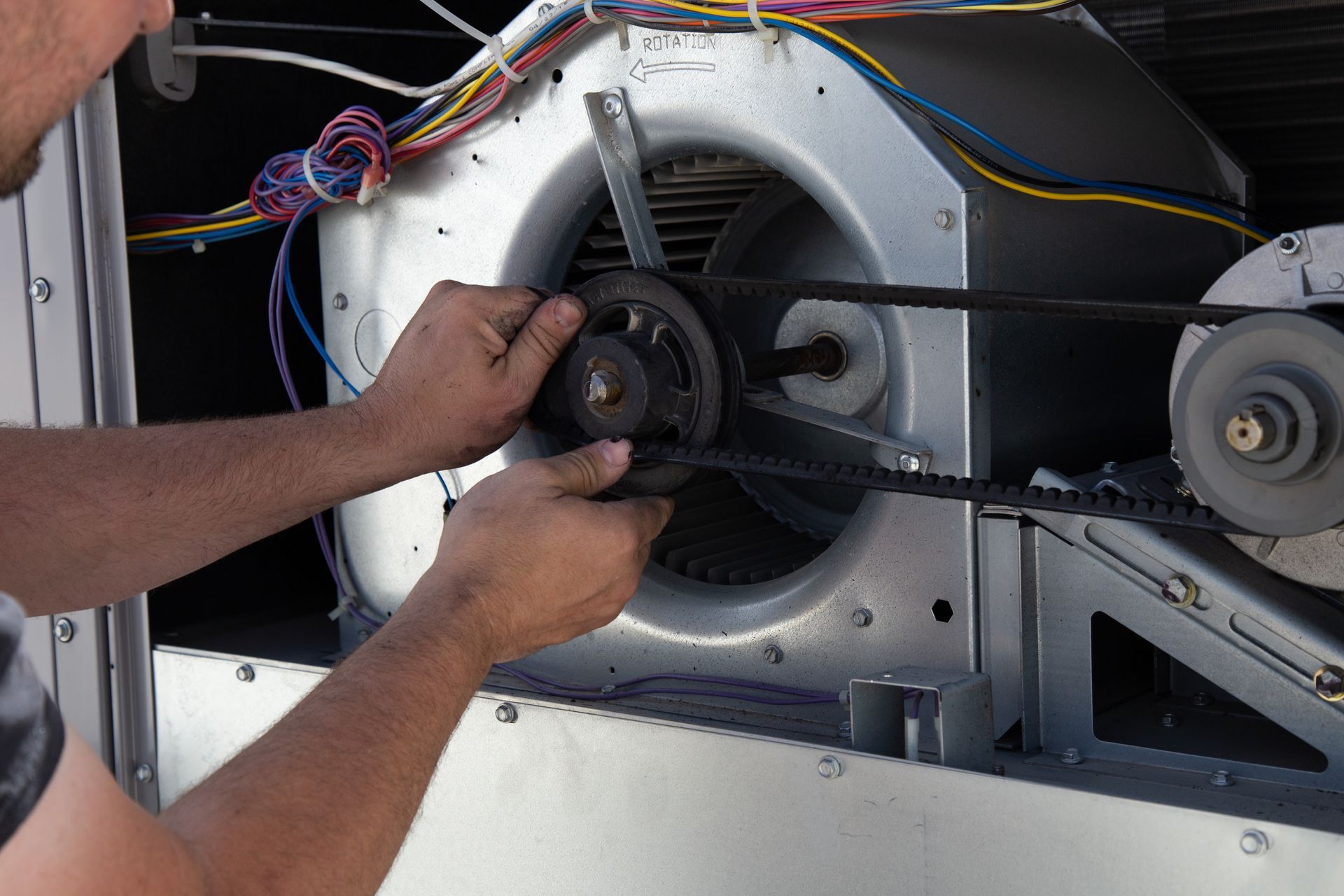

Proper installation ensures your system runs safely, efficiently, and lasts as long as possible. It's not just a matter of getting the equipment into place—it's about making sure it’s set up correctly, optimized for your space and needs, and ready to handle the demands of your operation. Working with a professional team like Anderson Mechanical means every detail, from airflow to electrical wiring, is handled with care.

Installing a compressor is a step-by-step process that begins well before the equipment is delivered. It starts with understanding the unique layout and requirements of your facility. A professional team will assess your space to determine the best location, check the ventilation, and make sure the area is safe and compliant with industry standards. This step is critical for keeping your system running without issues down the road.

Next comes equipment selection. Not every compressor is a fit for every job. Some facilities need rotary screw compressors for continuous operation, while others benefit from piston or scroll types. Professionals will help choose a unit based on the size of your building, the tools or systems you're powering, and your projected air usage. They’ll also look at things like noise levels and energy efficiency, so your compressor fits your operation without driving up energy bills or requiring excessive maintenance.

Electrical setup is another key piece. Compressors require a stable and adequate power supply, and that often means adjusting your facility’s electrical system to support it. This could involve installing new wiring, safety disconnects, or circuit protection. Getting this wrong could result in poor performance—or worse, a safety hazard. A professional installer makes sure the system is wired correctly and safely from day one.

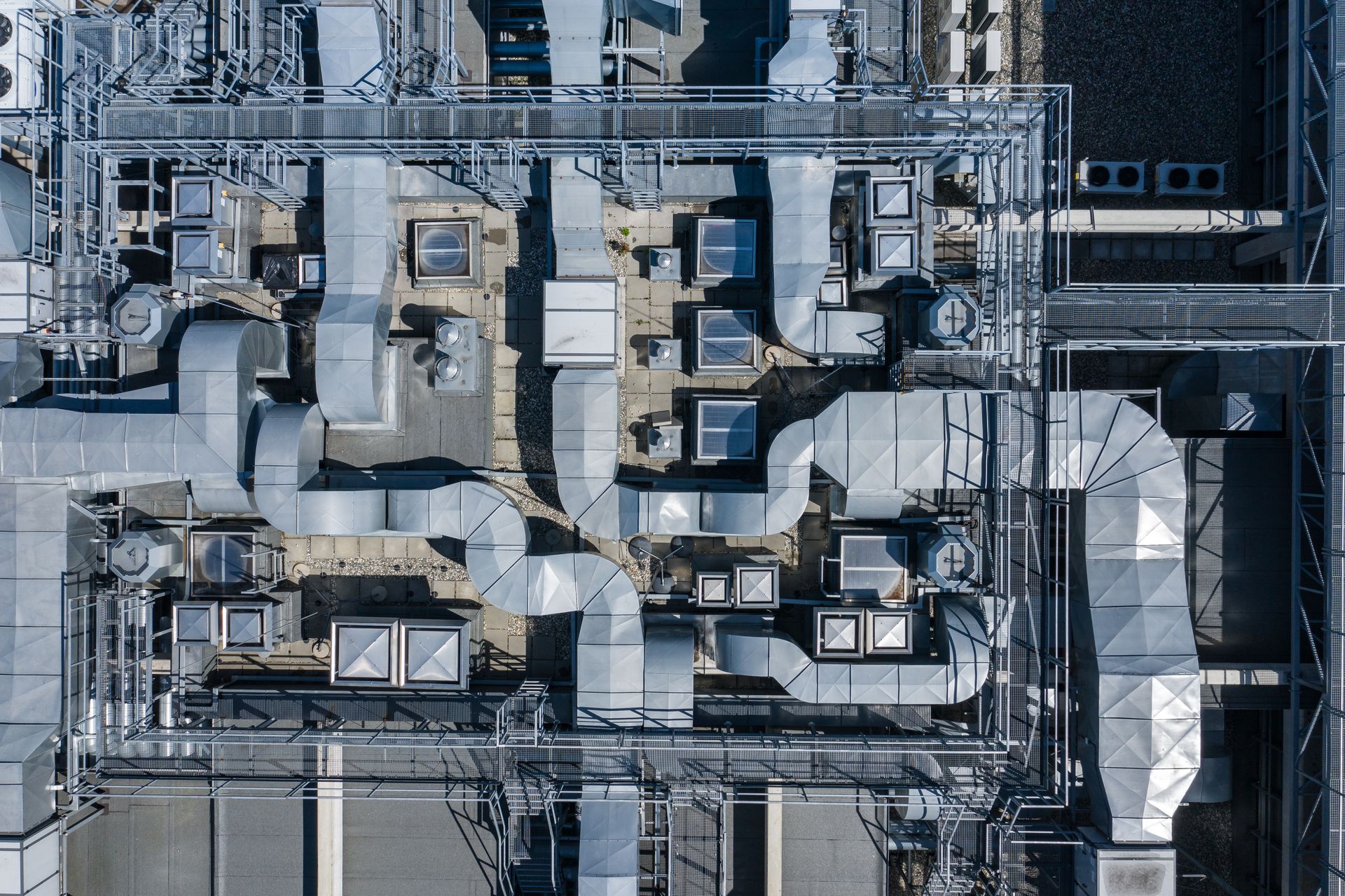

Once the compressor is in place, a properly designed piping system needs to be installed to distribute air to where it's needed. The type, size, and layout of this piping system have a direct impact on performance. Poorly designed piping can cause pressure drops, wasted energy, and inconsistent results at the point of use. Anderson Mechanical designs these systems with efficiency in mind, using materials that prevent corrosion and minimize leaks.

Air storage is another important consideration. Storage tanks provide a buffer for your compressed air system, helping to smooth out demand spikes and reduce compressor cycling. The tank size is chosen based on the size of the compressor and the usage profile of the building. This helps extend the life of the compressor and reduces wear and tear.

A critical but often overlooked part of compressor installation is ventilation and cooling. Compressors generate a lot of heat, and without a way to remove that heat, performance can suffer. In some cases, proper ventilation is as simple as choosing a well-ventilated room. In others, it may require ductwork or exhaust fans to move hot air out of the space. Professional installers factor this in from the start to protect your equipment and keep temperatures manageable.

Another benefit of hiring a professional installation team is that they take care of compliance. Whether it's local codes, OSHA standards, or manufacturer warranty requirements, you won’t have to worry about missing something important. Everything is documented and installed to spec, giving you peace of mind.

Once the system is installed, the job isn’t over. A quality installation includes thorough testing of the system to make sure everything is functioning as expected. The team will verify that air pressure is stable, check for leaks, confirm electrical safety, and make sure all components are operating properly. If your system includes automated controls or monitoring, they’ll configure and test those, too.

To finish up, the installation team will walk your staff through the operation of the system. This includes basic maintenance steps, how to recognize signs of trouble, and what to expect during routine service. This hands-on education can make a big difference in the longevity of the system.

Anderson Mechanical has been handling these types of installs for more than two decades. Their team brings industry experience, proper certifications, and a reputation for quality workmanship. They understand how compressor systems tie into the bigger picture of your facility’s operations, and they work to ensure everything runs as smoothly as possible from the moment the system is turned on.

Whether you're upgrading an outdated system, expanding into a larger facility, or installing a compressor for the first time, having the right team on your side makes all the difference. Anderson Mechanical provides customized installations based on your needs, your goals, and the demands of your environment.

Investing in professional compressor installation isn’t just about getting the job done—it’s about setting your business up for long-term success. With the right planning, equipment, and expert team, you’ll have a system that supports your operation day in and day out.

Boosting Energy Efficiency in Commercial Buildings: Smart HVAC Strategies for Kansas City Businesses

Unlocking Efficiency and Comfort: The Ultimate Guide to VRF Installation with Anderson Mechanical KC

Contact

Kansas City, MO; Lee Summit; Kansas City, KS; Johnson County; Jackson County

Subscribe

Subscribe for the latest news, updates, and insights from Anderson Mechanical.

Contact Us

We will get back to you as soon as possible.

Please try again later.